Package:

Package:  Loading:

Loading:

Deliver By Truck:

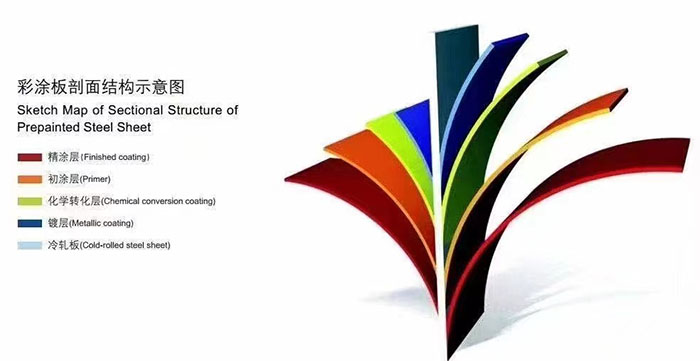

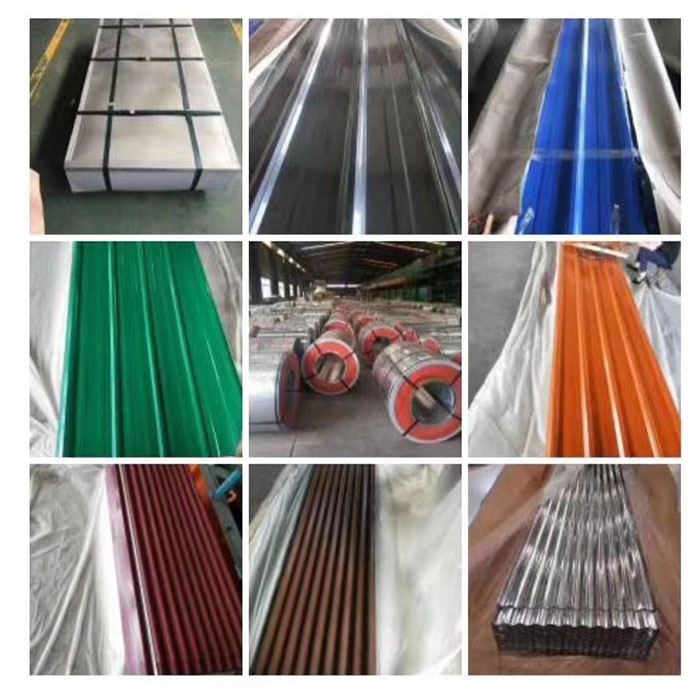

Deliver By Truck:  Application: Coated steel plate has light weight, beautiful appearance and good corrosion resistance, and can be directly processed. It provides a new type of raw material, which has good effects such as replacing wood with steel, efficient construction, energy saving, and pollution prevention. Color coating using galvanized steel sheet as substrate In addition to zinc protection, the organic coating on the zinc layer plays a role of covering and isolation, which can prevent the steel plate from rusting, and its service life is longer than that of the galvanized steel plate. According to the introduction, the life of coated plate is 50% longer than that of galvanized steel plate.

Application: Coated steel plate has light weight, beautiful appearance and good corrosion resistance, and can be directly processed. It provides a new type of raw material, which has good effects such as replacing wood with steel, efficient construction, energy saving, and pollution prevention. Color coating using galvanized steel sheet as substrate In addition to zinc protection, the organic coating on the zinc layer plays a role of covering and isolation, which can prevent the steel plate from rusting, and its service life is longer than that of the galvanized steel plate. According to the introduction, the life of coated plate is 50% longer than that of galvanized steel plate.