Products Details

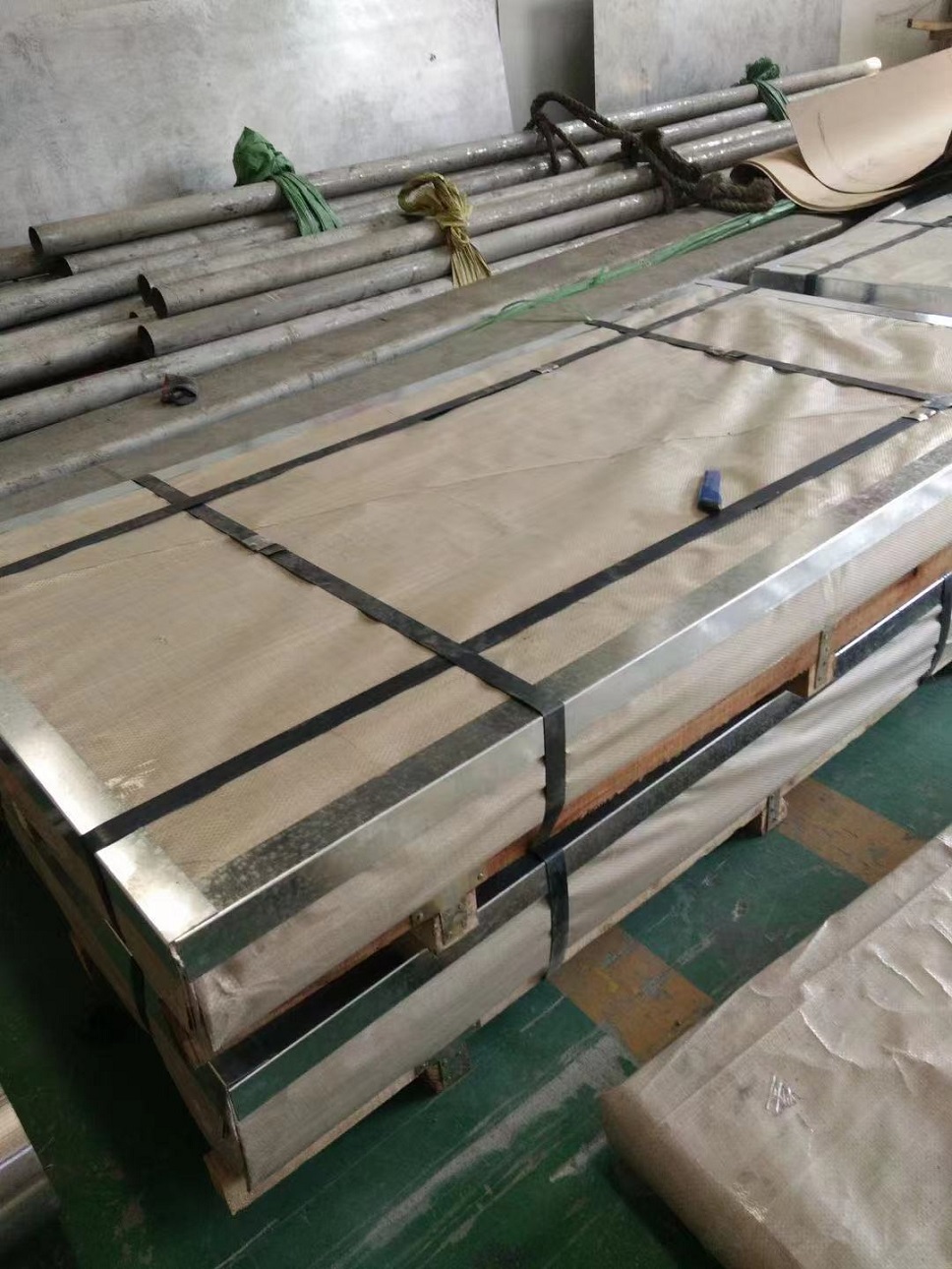

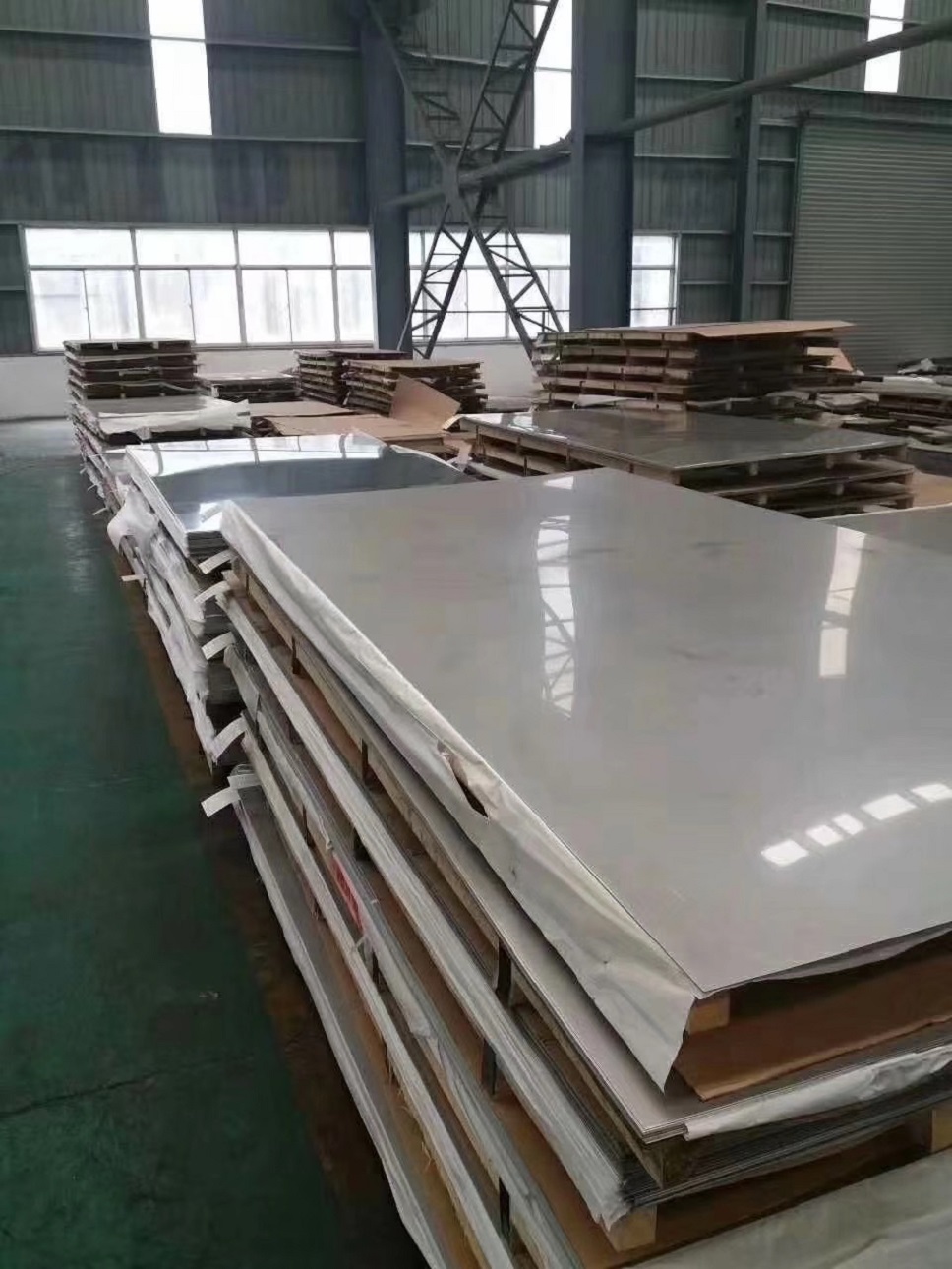

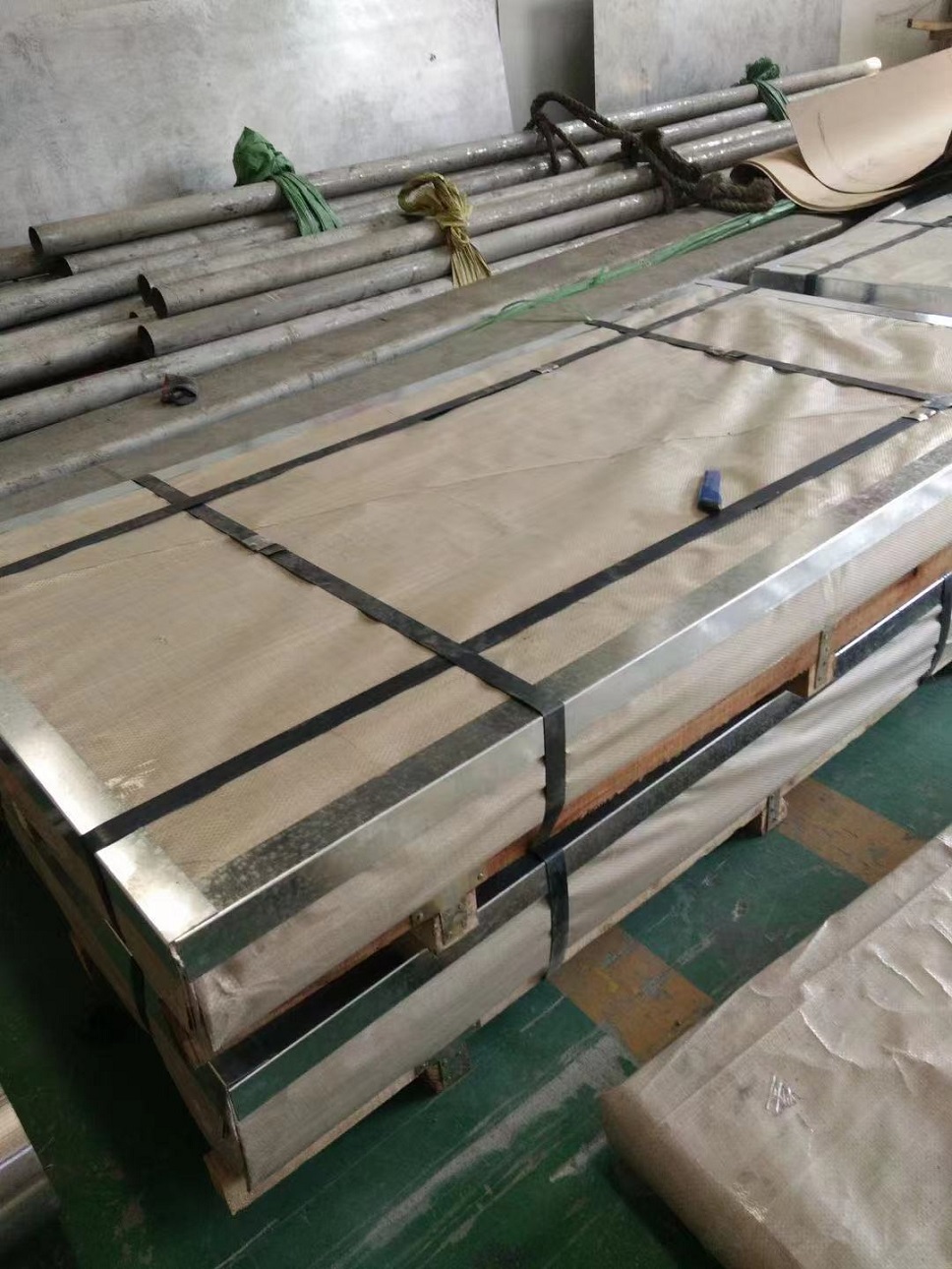

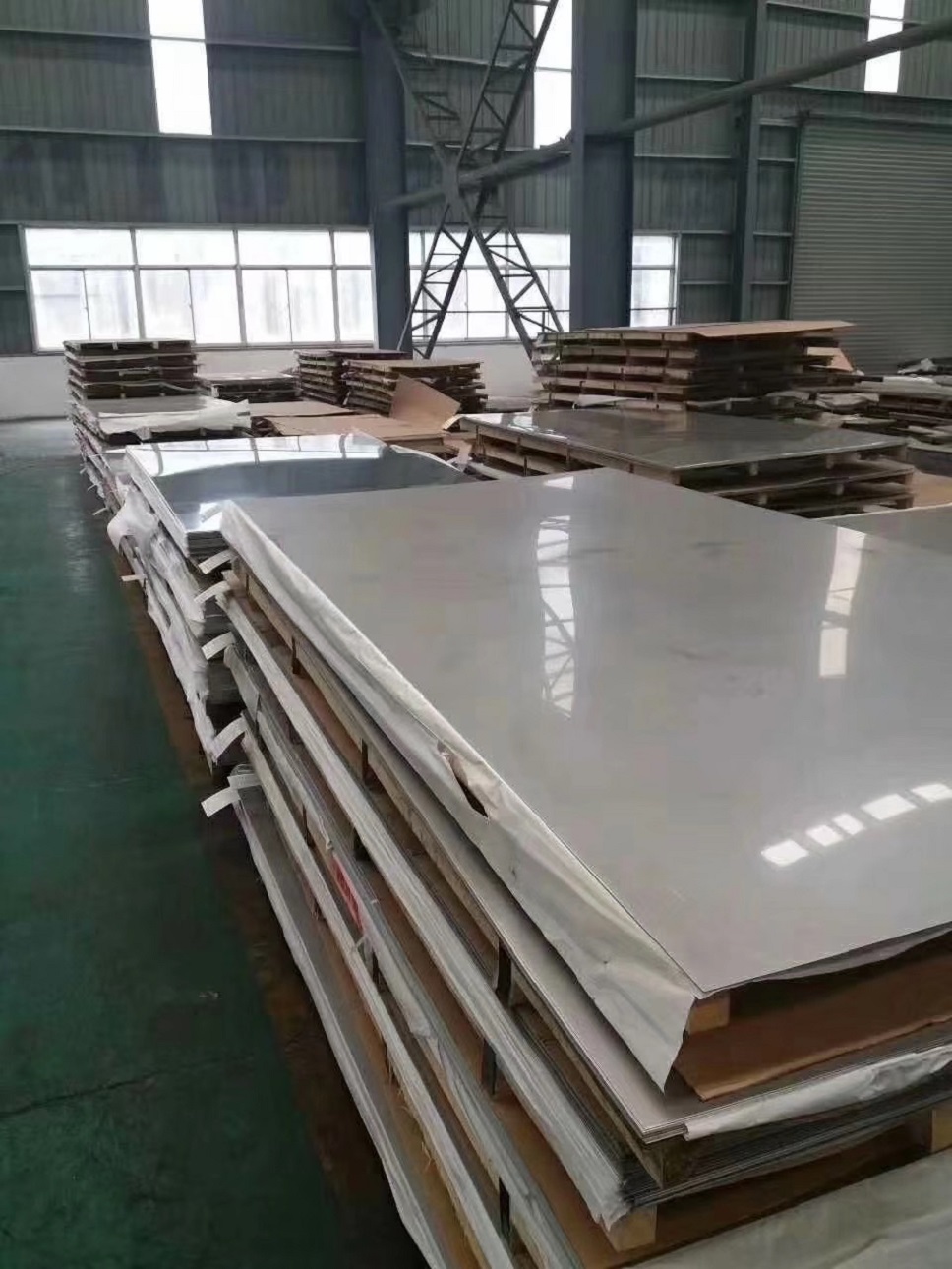

Stainless steel sheets are generally a general term for stainless steel sheets and acid-resistant steel sheets. At the beginning of this century, the development of stainless steel plates laid an important material and technical foundation for the development of modern industry and scientific and technological progress. There are many kinds of stainless steel plate steels with different properties, and it has gradually formed several major categories in the development process. According to the structure of the organization, it is divided into four categories: austenitic stainless steel plate, Martens stainless steel plate (including precipitation hardened stainless steel plate), ferritic stainless steel plate, and austenite plus ferrite duplex stainless steel plate. The main chemical composition or some characteristic elements in the steel plate are classified into chrome stainless steel plate, chrome nickel stainless steel plate, chrome nickel molybdenum stainless steel plate and low carbon stainless steel plate, high molybdenum stainless steel plate, high purity stainless steel plate and the like. According to the performance characteristics and application classification of steel plates, it is divided into nitric acid resistant stainless steel plates, sulfuric acid resistant stainless steel plates, pitting resistant stainless steel plates, stress corrosion resistant stainless steel plates, high strength stainless steel plates, etc. Classified according to the functional characteristics of the steel plate, it is divided into low temperature stainless steel plate, non-magnetic stainless steel plate, free cutting stainless steel plate, super plastic stainless steel plate and so on. The commonly used classification method is classified according to the structural characteristics of the steel plate and the chemical composition of the steel plate and the combination of the two. Generally, it is divided into martensite stainless steel plate, ferritic stainless steel plate, austenitic stainless steel plate, duplex stainless steel plate and precipitation hardening stainless steel plate, or divided into two categories: chrome stainless steel plate and nickel stainless steel plate. Widely used Typical applications: heat exchangers for machinery and papermaking equipment, mechanical equipment, dyeing equipment, film processing equipment, pipelines, exterior materials for buildings in coastal areas, etc. The stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acids, alkaline gases, solutions and other media. It is an alloy steel that is not easily rusted, but it is not absolutely rust-free. performance Packing:

Corrosion resistance The stainless steel sheet has the ability to withstand general corrosion similar to the unstable nichrome 304. Prolonged heating in the temperature range of chromium carbide may affect alloys 321 and 347 in harsh corrosive media. Mainly used in high temperature applications, high temperature applications require strong sensitization of materials to prevent intergranular corrosion at lower temperatures. High temperature oxidation resistance Stainless steel plates have high temperature oxidation resistance, but the oxidation rate is affected by inherent factors such as the exposed environment and product morphology. Physical properties The total heat transfer coefficient of the metal depends on other factors, in addition to the thermal conductivity of the metal. In most cases, the film's heat dissipation coefficient, scale and metal surface condition. Stainless steel keeps the surface clean and tidy, so its heat transfer is better than other metals with higher thermal conductivity. Liaocheng Suntory Stainless Steel provides technical standards for stainless steel plates. High-strength stainless steel plates with excellent corrosion resistance, bending processability and weld site toughness, and excellent stamping performance at welded parts. Specifically, it contains C: 0.02% or less, N: 0.02% or less, Cr: 11% or more and less than 17%, and an appropriate content of Si, Mn, P, S, Al, Ni, and satisfies 12 ≤ Cr Mo 1.5Si ≤ 17, 1 ≤ Ni 30 (CN) 0.5 (Mn Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3Mo ≥ 16.0, 0.006 ≤ CN ≤ 0.030 stainless steel plate is heated to 850 ~ 1250 ° C, and then carried out at 1 ° C / s The above heat treatment for cooling rate cooling. Thus, it can be a structure containing a martensite having a volume fraction of 12% or more, a high strength of 730 MPa or more, corrosion resistance, bending workability, and a high-strength stainless steel sheet excellent in weld heat-affected zone toughness. By using Mo, B, etc., the press working property of the welded portion can be remarkably improved. The flame of oxygen plus gas cannot cut stainless steel because the stainless steel is not easily oxidized.

Corrosion resistance The stainless steel sheet has the ability to withstand general corrosion similar to the unstable nichrome 304. Prolonged heating in the temperature range of chromium carbide may affect alloys 321 and 347 in harsh corrosive media. Mainly used in high temperature applications, high temperature applications require strong sensitization of materials to prevent intergranular corrosion at lower temperatures. High temperature oxidation resistance Stainless steel plates have high temperature oxidation resistance, but the oxidation rate is affected by inherent factors such as the exposed environment and product morphology. Physical properties The total heat transfer coefficient of the metal depends on other factors, in addition to the thermal conductivity of the metal. In most cases, the film's heat dissipation coefficient, scale and metal surface condition. Stainless steel keeps the surface clean and tidy, so its heat transfer is better than other metals with higher thermal conductivity. Liaocheng Suntory Stainless Steel provides technical standards for stainless steel plates. High-strength stainless steel plates with excellent corrosion resistance, bending processability and weld site toughness, and excellent stamping performance at welded parts. Specifically, it contains C: 0.02% or less, N: 0.02% or less, Cr: 11% or more and less than 17%, and an appropriate content of Si, Mn, P, S, Al, Ni, and satisfies 12 ≤ Cr Mo 1.5Si ≤ 17, 1 ≤ Ni 30 (CN) 0.5 (Mn Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3Mo ≥ 16.0, 0.006 ≤ CN ≤ 0.030 stainless steel plate is heated to 850 ~ 1250 ° C, and then carried out at 1 ° C / s The above heat treatment for cooling rate cooling. Thus, it can be a structure containing a martensite having a volume fraction of 12% or more, a high strength of 730 MPa or more, corrosion resistance, bending workability, and a high-strength stainless steel sheet excellent in weld heat-affected zone toughness. By using Mo, B, etc., the press working property of the welded portion can be remarkably improved. The flame of oxygen plus gas cannot cut stainless steel because the stainless steel is not easily oxidized.

Pre Galvanized Steel Pipe,

* mm steel plate,

76mm Steel Pipe,

sch 80 seamless pipe,

1.25 Inch Stainless Steel Pipe,

High-Strength Steel Plate,

Seamless Stainless Steel Pipe,

"High temperature pipeline",

Stainless Steel Plumbing Pipe,

1.75 Stainless Tubing,

Corrosion resistance The stainless steel sheet has the ability to withstand general corrosion similar to the unstable nichrome 304. Prolonged heating in the temperature range of chromium carbide may affect alloys 321 and 347 in harsh corrosive media. Mainly used in high temperature applications, high temperature applications require strong sensitization of materials to prevent intergranular corrosion at lower temperatures. High temperature oxidation resistance Stainless steel plates have high temperature oxidation resistance, but the oxidation rate is affected by inherent factors such as the exposed environment and product morphology. Physical properties The total heat transfer coefficient of the metal depends on other factors, in addition to the thermal conductivity of the metal. In most cases, the film's heat dissipation coefficient, scale and metal surface condition. Stainless steel keeps the surface clean and tidy, so its heat transfer is better than other metals with higher thermal conductivity. Liaocheng Suntory Stainless Steel provides technical standards for stainless steel plates. High-strength stainless steel plates with excellent corrosion resistance, bending processability and weld site toughness, and excellent stamping performance at welded parts. Specifically, it contains C: 0.02% or less, N: 0.02% or less, Cr: 11% or more and less than 17%, and an appropriate content of Si, Mn, P, S, Al, Ni, and satisfies 12 ≤ Cr Mo 1.5Si ≤ 17, 1 ≤ Ni 30 (CN) 0.5 (Mn Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3Mo ≥ 16.0, 0.006 ≤ CN ≤ 0.030 stainless steel plate is heated to 850 ~ 1250 ° C, and then carried out at 1 ° C / s The above heat treatment for cooling rate cooling. Thus, it can be a structure containing a martensite having a volume fraction of 12% or more, a high strength of 730 MPa or more, corrosion resistance, bending workability, and a high-strength stainless steel sheet excellent in weld heat-affected zone toughness. By using Mo, B, etc., the press working property of the welded portion can be remarkably improved. The flame of oxygen plus gas cannot cut stainless steel because the stainless steel is not easily oxidized.

Corrosion resistance The stainless steel sheet has the ability to withstand general corrosion similar to the unstable nichrome 304. Prolonged heating in the temperature range of chromium carbide may affect alloys 321 and 347 in harsh corrosive media. Mainly used in high temperature applications, high temperature applications require strong sensitization of materials to prevent intergranular corrosion at lower temperatures. High temperature oxidation resistance Stainless steel plates have high temperature oxidation resistance, but the oxidation rate is affected by inherent factors such as the exposed environment and product morphology. Physical properties The total heat transfer coefficient of the metal depends on other factors, in addition to the thermal conductivity of the metal. In most cases, the film's heat dissipation coefficient, scale and metal surface condition. Stainless steel keeps the surface clean and tidy, so its heat transfer is better than other metals with higher thermal conductivity. Liaocheng Suntory Stainless Steel provides technical standards for stainless steel plates. High-strength stainless steel plates with excellent corrosion resistance, bending processability and weld site toughness, and excellent stamping performance at welded parts. Specifically, it contains C: 0.02% or less, N: 0.02% or less, Cr: 11% or more and less than 17%, and an appropriate content of Si, Mn, P, S, Al, Ni, and satisfies 12 ≤ Cr Mo 1.5Si ≤ 17, 1 ≤ Ni 30 (CN) 0.5 (Mn Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3Mo ≥ 16.0, 0.006 ≤ CN ≤ 0.030 stainless steel plate is heated to 850 ~ 1250 ° C, and then carried out at 1 ° C / s The above heat treatment for cooling rate cooling. Thus, it can be a structure containing a martensite having a volume fraction of 12% or more, a high strength of 730 MPa or more, corrosion resistance, bending workability, and a high-strength stainless steel sheet excellent in weld heat-affected zone toughness. By using Mo, B, etc., the press working property of the welded portion can be remarkably improved. The flame of oxygen plus gas cannot cut stainless steel because the stainless steel is not easily oxidized.