| Standard | Grade | Chemical Compsition (Max %) | |||||||||

| C | Mn | Ni | Si | P | S | Cr | Cu | Mo | N | ||

| A240 | AL6XN | ≤0.02 | ≤2.00 | 23.5-25.5 | ≤1.00 | ≤0.04 | ≤0.01 | 20.00-22.00 | ≤0.75 | 6.0-7.0 | 0.18-0.25 |

| Standard | Grade | Tensile Strength | Yield Strength | Elongation |

| (MPa) | (MPa) | (%) | ||

| A240 | AL6XN | ≥650 | ≥295 | ≥35 |

| Hot rolled | AL6XN | ≥744 | ≥365 | ≥47 |

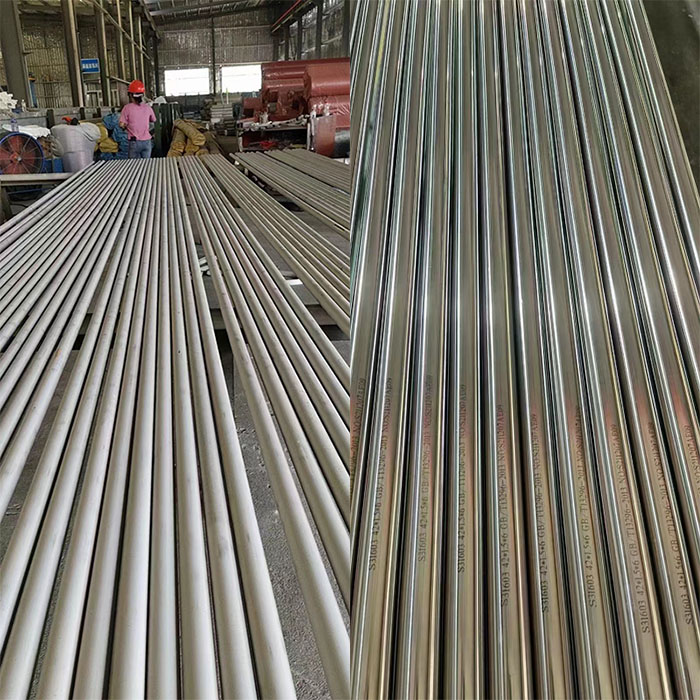

The surface of the stainless steel pipe is as follows: AP: Acid pickling (Anneal treatment & Passivation) /(Acid pickling MP: Mechanical grinding or mechanical polishing (Mechanical Polish) BA: Bright Anneal treatment (Bright Annealing) EP: Electrolytic Polishing (Electro Polish) V+V: vacuum double-dissolving ultra-clean steel or double vacuum melting Vim(Vacuum Induction Melting)+Var(Vacuum Arc Remelting), Pipe material processing flow,; EP: bright annealing--nondestructive testing-_>-chemical polishing-->electropolishing; BA: bright annealing--nondestructive testing--second cleaning; CP/AP heat treatment --> nondestructive testing -- chemical polishing; 6. Package:

The surface of the stainless steel pipe is as follows: AP: Acid pickling (Anneal treatment & Passivation) /(Acid pickling MP: Mechanical grinding or mechanical polishing (Mechanical Polish) BA: Bright Anneal treatment (Bright Annealing) EP: Electrolytic Polishing (Electro Polish) V+V: vacuum double-dissolving ultra-clean steel or double vacuum melting Vim(Vacuum Induction Melting)+Var(Vacuum Arc Remelting), Pipe material processing flow,; EP: bright annealing--nondestructive testing-_>-chemical polishing-->electropolishing; BA: bright annealing--nondestructive testing--second cleaning; CP/AP heat treatment --> nondestructive testing -- chemical polishing; 6. Package:  7. Delivery:

7. Delivery:  8. Application of AL-6XN (N08367) super austenitic stainless steel: Reverse osmosis desalination equipment and pumps FGD scrubber Chemical Process Tanks and Piping seawater heat exchanger Tall Oil Distillation Columns and Packing Offshore Oil and Gas Production Equipment Pulp bleach plant washers, vats, press rolls and pipes

8. Application of AL-6XN (N08367) super austenitic stainless steel: Reverse osmosis desalination equipment and pumps FGD scrubber Chemical Process Tanks and Piping seawater heat exchanger Tall Oil Distillation Columns and Packing Offshore Oil and Gas Production Equipment Pulp bleach plant washers, vats, press rolls and pipes