Production Description:

Standard:EN 10216-1

Grade:P195TR1, P195TR 2, P235TR1, P235TR2, P265TR1, P265TR2

Deliver condition:Normalization

Size Range:OD 70MM-610MM , Thickness 6MM-35MM

Tolerance:As EN 10216-1

Length:As request

MTC:EN 10204/3.1

Chemical Composition: | Grade | Chemical Composition% | ||||||

| Processing | Condition | C | Si | Mn | P | S | |

| Max | Max | Max | Max | Max | |||

| P195TR1 | Hot Form | Normalization | 0.13 | 0.35 | 0.7 | 0.025 | 0.02 |

| P195TR2 | Hot Form | Normalization | 0.13 | 0.35 | 0.7 | 0.025 | 0.02 |

| P235TR1 | Hot Form | Normalization | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 |

| P235TR2 | Hot Form | Normalization | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 |

| P265TR1 | Hot Form | Normalization | 0.2 | 0.4 | 1.4 | 0.025 | 0.02 |

| P265TR2 | Hot Form | Normalization | 0.2 | 0.4 | 1.4 | 0.025 | 0.02 |

| Grade | Mechanical Properties | |||||

| Yeild | Tensile | Elongation | Impact Value | |||

| Min Mpa | Min% | min J | ||||

| T in mm | Mpa | ︱ | Test Degree | |||

| ≤16 | >16 ≤40 | 0℃ | -10℃ | |||

| P195TR1 | 195 | 185 | 320-440 | 27 | -- | -- |

| P195TR 2 | 195 | 185 | 320-440 | 27 | 40 | 28 |

| P235TR1 | 235 | 225 | 360-500 | 25 | -- | -- |

| P235TR2 | 235 | 225 | 360-500 | 25 | 40 | 28 |

| P265TR1 | 265 | 255 | 410-570 | 21 | -- | -- |

| P265TR2 | 265 | 255 | 410-570 | 21 | 40 | 28 |

| Remark:T is Thickness; ︱is Lengthways | ||||||

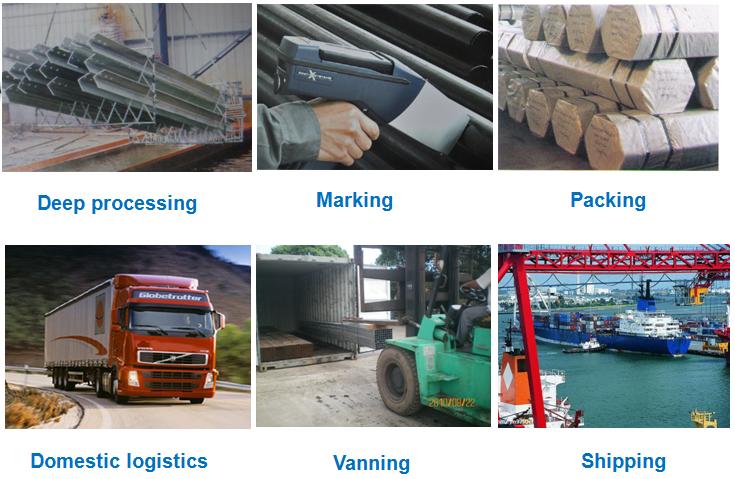

Our Service:

Our Service:  RFQ: Q1: Are you manufacture or Trader A: We are both manufacture and trader Q2: Can you offer sample? A: Sample small one can be offered by free, but buyer should pay the express fee Q3: Can you offer processing service? A: We can offer cutting, drilling, painting, coat powder etc... Q4: What is your advantage on steel? A: We can customize steel structure accoridng to buy's drawings or request. Q5: How about your logistic service? A: we have professional logistic team who has rich experience on shipping, can offer the steady and quality ship line. Market:

RFQ: Q1: Are you manufacture or Trader A: We are both manufacture and trader Q2: Can you offer sample? A: Sample small one can be offered by free, but buyer should pay the express fee Q3: Can you offer processing service? A: We can offer cutting, drilling, painting, coat powder etc... Q4: What is your advantage on steel? A: We can customize steel structure accoridng to buy's drawings or request. Q5: How about your logistic service? A: we have professional logistic team who has rich experience on shipping, can offer the steady and quality ship line. Market: