1. Grade: AL-6XN (N08367) Material designation: AL-6XN super austenitic stainless steel American grade: UNS N08367 Chinese brand: 00Cr21Ni24Mo6N 2. Chemical Composition: | Standard | Grade | Chemical Compsition (Max %) |

| C | Mn | Ni | Si | P | S | Cr | Cu | Mo | N |

| A240 | AL6XN | ≤0.02 | ≤2.00 | 23.5-25.5 | ≤1.00 | ≤0.04 | ≤0.01 | 20.00-22.00 | ≤0.75 | 6.0-7.0 | 0.18-0.25 |

3. Mechanical Properties: | Standard | Grade | Tensile Strength | Yield Strength | Elongation |

| (MPa) | (MPa) | (%) |

| A240 | AL6XN | ≥650 | ≥295 | ≥35 |

| Hot rolled | AL6XN | ≥744 | ≥365 | ≥47 |

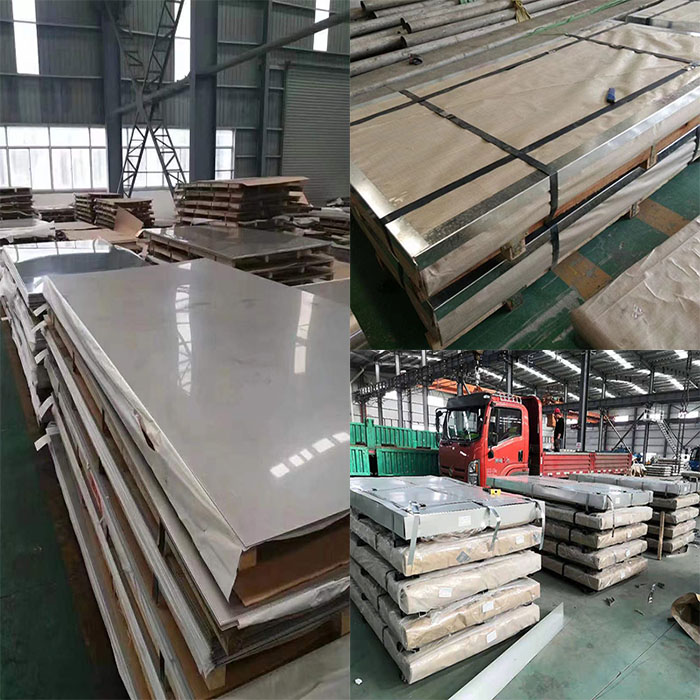

4. Detail Description: AL-6XN is a typical 6 molybdenum (high molybdenum content 6.3%) super austenitic stainless steel. Its resistance to chloride pitting, crevice corrosion and stress corrosion is better than that of the 3 series stainless steel, and its cost is lower than that of corrosion-resistant nickel-based alloys. It exhibits good anti-corrosion properties in various severe corrosive environments, and is suitable for high chloride aqueous solutions and chloride corrosive environments. Used in a variety of high chloride environments: bleach (sodium hypochlorite), halogen and salt or chemicals with high seawater content. Material name: high molybdenum super austenitic stainless steel, grade: AL6XN 1). Overview of AL-6XN (N08367) Super Austenitic Stainless Steel: AL-6XN (N08367) is a typical 6 molybdenum (high molybdenum content 6.3%) super austenitic stainless steel. The resistance to chloride pitting, crevice corrosion and stress corrosion is better than that of 3 series stainless steel, and the cost is lower than that of corrosion-resistant nickel-based alloys. AL-6XN (N08367) super austenitic stainless steel shows good corrosion resistance in various severe corrosive environments, and is suitable for high chloride aqueous solutions and chloride corrosion environments. Used in a variety of high chloride environments: bleach (sodium hypochlorite), halogen and salt or chemicals with high seawater content. AL-6XN (N08367) super austenitic stainless steel is also a super austenitic stainless steel with excellent resistance to chloride ion pitting and crevice corrosion. As a corrosion-resistant alloy with good cost performance, its comprehensive corrosion resistance Compared with 316L, it has a great leap, and at the same time, its corrosion resistance is close to other corrosion-resistant nickel-based alloys such as C-276, and the cost advantage is obvious. Because of the significant nitrogen added to the alloy, the Al-6XN material has a higher tensile strength than conventional austenitic stainless steels (such as 304, 316, 317, etc.), while maintaining excellent material toughness and impact strength, ASME standard The allowable stress value specified in Al-6XN is 40% higher than that of 316L, and nearly double that of copper-nickel alloy. 2). Main ingredients of AL-6XN (N08367) Cr: 21% Ni: 24% Mo: 6% N: 0.2% Application areas: Offshore platforms, nuclear industry, pharmaceutical, paper and food industry equipment; flue gas desulfurization pipeline lining; petrochemical distillation towers; high-pressure water heaters; thin-walled condensing pipes for seawater cooling; steam surface condensers and household multifunctional heating furnaces. 3). The physical and mechanical properties of AL-6XN (N08367) super austenitic stainless steel (21℃ at room temperature): (1). Density of AL-6XN (N08367) stainless steel: 8.24g/cm3. (2). AL-6XN (N08367) stainless steel tensile strength: σb≥744Mpa. (3). AL-6XN (N08367) stainless steel yield strength: σb≥365Mpa. (4). AL-6XN (N08367) stainless steel elongation rate: δ≥47%. Four, AL-6XN (N08367) super austenitic stainless steel material characteristics: Compared with the standard 300 series alloy, AL-6XN (N08367) stainless steel has higher resistance to pitting, crevice corrosion and pressure crevice corrosion to chloride ions. In stainless steel, Cr, Mo, Ni, and C are resistant to different media. Corrosive. Cr is the representative of corrosion resistance in natural and oxidizing environments. The increase in the content of Cr, Mo, Ni increases the resistance to pitting corrosion, nickel provides the austenite structure, and nickel molybdenum increases the pressure crevice corrosion resistance to chloride ions and reduces the resistance The corrosion resistance of the environment. High nickel (24%), molybdenum (6.3%) AL-6XN stainless steel has good resistance to pressure crevice corrosion. Molybdenum has the ability to resist pitting corrosion of chloride ions, and nickel further enhances the ability to resist pitting corrosion, and can provide higher strength than 300 austenitic stainless steel, so it is often used in thinner parts of equipment. In AL-6XN stainless steel, the higher content of chromium, molybdenum, and nickel also provides the corrosion resistance of stainless steel during forming and welding. In addition, AL-6XN stainless steel also has the following (1). Excellent resistance to pitting and crevice corrosion in a medium containing chloride ions. (2). Excellent stress corrosion resistance under the medium of sodium chloride salt solution. (3). High strength, good toughness. 5. Main application of AL-6XN (N08367) super austenitic stainless steel: The high chromium, molybdenum, nickel and nitrogen of AL-6XN make AL-6XN have better resistance to chloride ion pitting corrosion and crevice corrosion, which makes AL-6XN used in many environments: flue gas desulfurization spray tower; reverse osmosis method Seawater desalination equipment and pumps; chemical reactors and pipelines; heat exchangers using seawater media; crude oil splitting distillation towers and metal packing; marine oil and gas extraction equipment; scrubber drums, press rolls, tanks, pipes, etc. in the pulp bleaching system . 6. Packing:

7. Advantage:

Raw material is from Top manufacture which promise the high quality.

Accurate technology confirm the exact size tolerance.

Efficient sales team give you proper proposal.

After-sales team offer and support for product guarantee.

8. Quality Control:

9. Our Service:

10. RFQ:

Q1: Are you manufacture or Trader

A: We are both manufacture and trader

Q2: Can you offer sample?

A: Sample small one can be offered by free, but buyer should pay the express fee

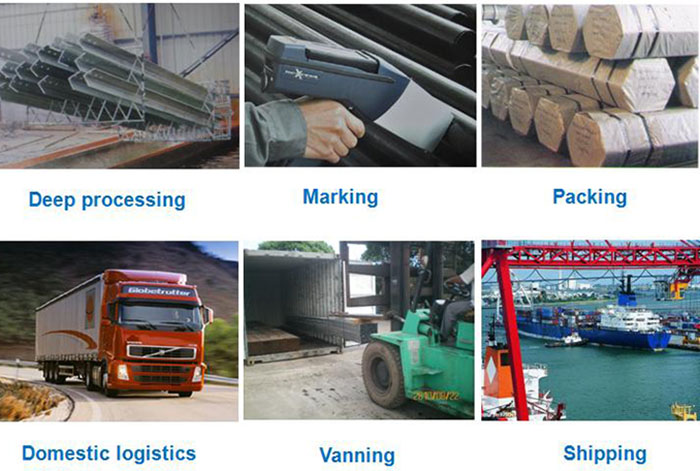

Q3: Can you offer processing service?

A: We can offer cutting, drilling, painting, coat powder etc...

Q4: What is your advantage on steel?

A: We can customize steel structure accoridng to buy's drawings or request.

Q5: How about your logistic service?

A: we have professional logistic team who has rich experience on shipping, can offer the steady and quality ship line.

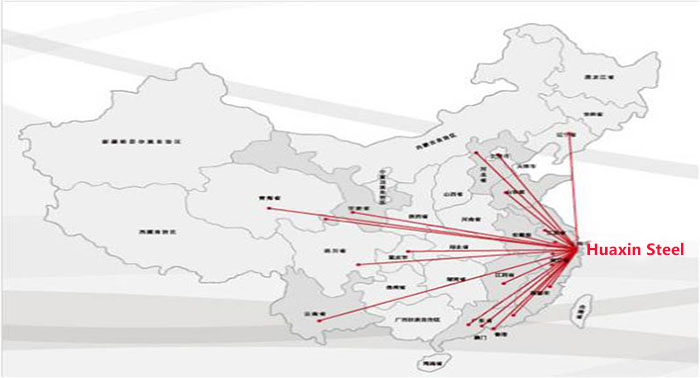

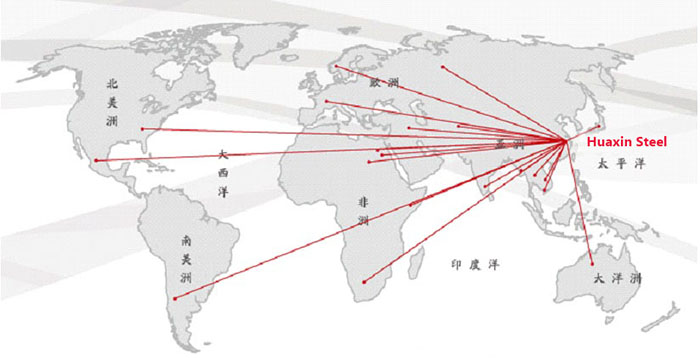

11. Market:

We have built a long-term and stable cooperation relation with customers in domestic , such as Shanghai, Jiangsu, Zhejiang, Anhui, Shandong, Jiangxi, Qinghai, Liaoning, Hainan and so on.

For overseas, our main client from South Asia, Africa, South America like Singapore, Vietnam, Brazil, Ghana, New Zealand, Spain, Mauritius, Dubai etc.