Grade:42CrMo4, 4140, 42CrMo

Deliver Condition:Hot rolling, Normalization Rolling

Size Range:OD 70MM-610MM , Thickness 6MM-35MM

Tolerance: According to EN 10210-2:2006

Length:As request

Certificate: FPC

Chemical Composition:

| Grade | Chemical Compostion % | |||||||

| Standard | C | Si | Mn | Cr | Mo | P | s | |

| Max | Max | Max | Max | Max | Max | Max | ||

| 42CrMo4 | EN10083 | 0.38-0.45 | 0.4 | 0.6-0.9 | 0.9-1.2 | 0.15-0.3 | 0.025 | 0.035 |

| 4140 | ASTM A29/A29M-04 | 0.33-0.48 | 0.15-0.35 | 0.75-1.0 | 0.8-1.1 | 0.15-0.25 | 0.03 | 0.03 |

| 42CrMo | GB/T 3077 | 0.38-0.45 | 0.17-0.37 | 0.4-0.7 | 0.09-1.2 | 0.15-0.25 | 0.035 | 0.035 |

| Grade | Mechanical Properties | ||||||

| Standard | Yield Strength | Tensile Strength | elongation | Impact Value | Hardness | αkv | |

| Min Mpa | Min Mpa | Min%︱ | min J | HB | min | ||

| 42CrMo4 | EN10083 | 930 | 1080 | 26 | ≥63 | ≤217 | 78 |

| 4140 | ASTM A29/A29M-04 | 610 | 795 | 22 | -- | 241 | 157 |

| 42CrMo | GB/T 3077 | 275 | 410-560 | ≥12 | ≥63 | ≤217 | 78 |

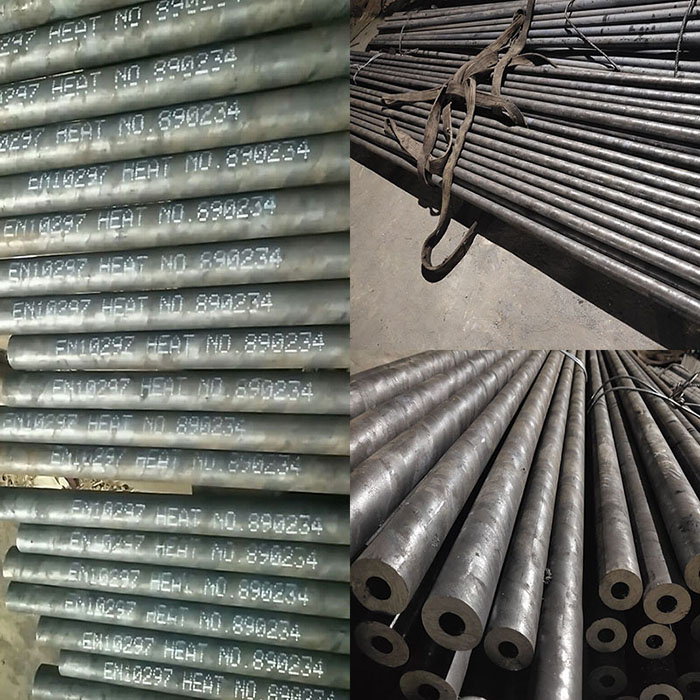

Production Show:

Application: The alloy seamless pipe is a kind of seamless steel pipe, and its performance is much higher than that of the ordinary seamless steel pipe. Because the steel pipe contains more Cr, its high temperature resistance, low temperature resistance and corrosion resistance are better than other seamless steel pipes. So the alloy tube is widely used in petroleum, chemical, electric power, boiler and other industries. 4140 thick-walled seamless pipe is ultra-high strength steel with high strength and toughness, good hardenability,no obvious temper brittleness, high fatigue limit and resistance to multiple impacts after quenching and tempering, low temperature Good impact toughness. The steel is suitable for the manufacture of large and medium-sized plastic molds requiring a certain strength and toughness. 4140 thick-walled seamless pipe characteristics and scope of application: high strength, high hardenability, good toughness, small deformation during quenching, high creep strength and long-lasting strength at high temperatures. Forgings requiring higher strength and larger quenching section than 35CrMo steel, such as large gears for locomotive traction, supercharger transmission gears, rear axles, extremely loaded connecting rods and spring clips, can also be used Oil deep well drill pipe joints and fishing tools below 2000m, and can be used for molds of bending machines, etc.

Application: The alloy seamless pipe is a kind of seamless steel pipe, and its performance is much higher than that of the ordinary seamless steel pipe. Because the steel pipe contains more Cr, its high temperature resistance, low temperature resistance and corrosion resistance are better than other seamless steel pipes. So the alloy tube is widely used in petroleum, chemical, electric power, boiler and other industries. 4140 thick-walled seamless pipe is ultra-high strength steel with high strength and toughness, good hardenability,no obvious temper brittleness, high fatigue limit and resistance to multiple impacts after quenching and tempering, low temperature Good impact toughness. The steel is suitable for the manufacture of large and medium-sized plastic molds requiring a certain strength and toughness. 4140 thick-walled seamless pipe characteristics and scope of application: high strength, high hardenability, good toughness, small deformation during quenching, high creep strength and long-lasting strength at high temperatures. Forgings requiring higher strength and larger quenching section than 35CrMo steel, such as large gears for locomotive traction, supercharger transmission gears, rear axles, extremely loaded connecting rods and spring clips, can also be used Oil deep well drill pipe joints and fishing tools below 2000m, and can be used for molds of bending machines, etc. Loading:  Mill Certificate:

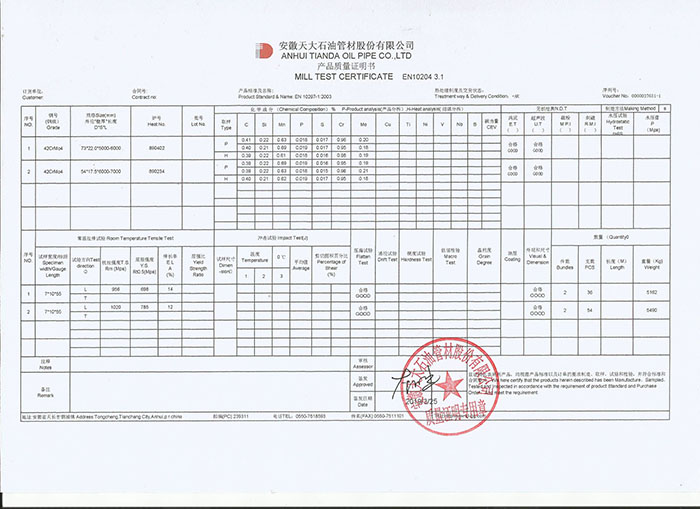

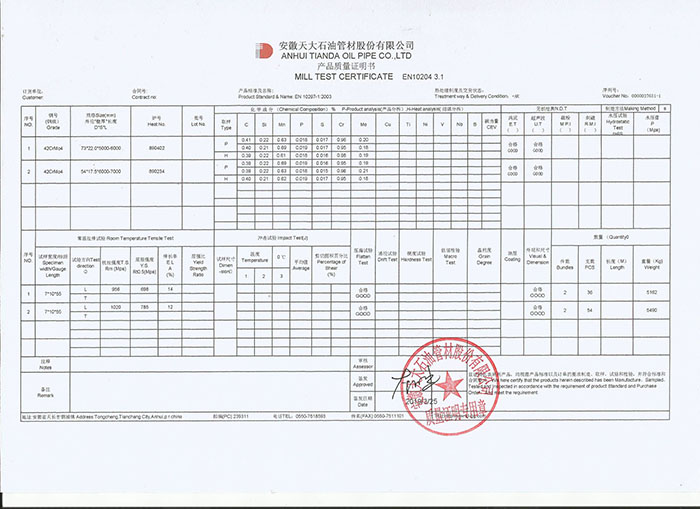

Mill Certificate:  Advantage: Raw material is from Top manufacture which promise the high quality. Accurate technology confirm the exact size tolerance. Efficient sales team give you proper proposal. After-sales team offer and support for product guarantee. Quality Control:

Advantage: Raw material is from Top manufacture which promise the high quality. Accurate technology confirm the exact size tolerance. Efficient sales team give you proper proposal. After-sales team offer and support for product guarantee. Quality Control:  Our Service:

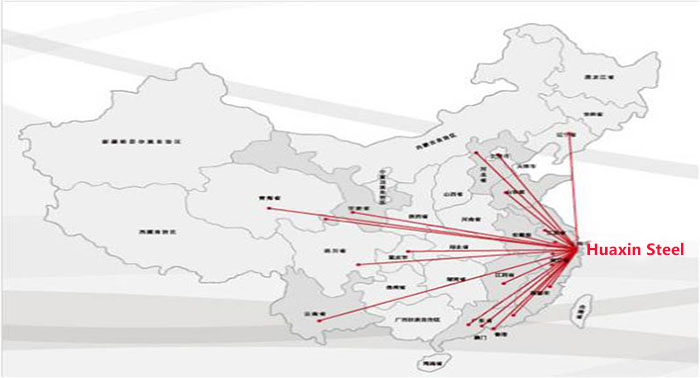

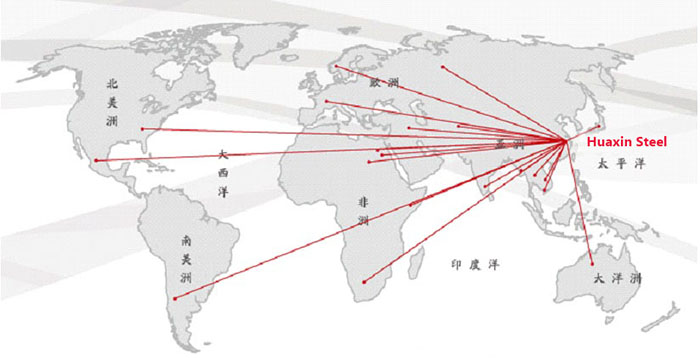

Our Service:  RFQ: Q1: Are you manufacture or Trader A: We are both manufacture and trader Q2: Can you offer sample? A: Sample small one can be offered by free, but buyer should pay the express fee Q3: Can you offer processing service? A: We can offer cutting, drilling, painting, coat powder etc... Q4: What is your advantage on steel? A: We can customize steel structure accoridng to buy's drawings or request. Q5: How about your logistic service? A: we have professional logistic team who has rich experience on shipping, can offer the steady and quality ship line. Market: We have built a long-term and stable cooperation relation with customers in domestic , such as Shanghai, Jiangsu, Zhejiang, Anhui,Shandong, Jiangxi, Qinghai, Liaoning, Hainan and so on. For overseas, our main client from South Asia, Africa, South America like Singapore, Vietnam, Brazil, Ghana, New Zealand, Spain, Mauritius, Dubai etc.

RFQ: Q1: Are you manufacture or Trader A: We are both manufacture and trader Q2: Can you offer sample? A: Sample small one can be offered by free, but buyer should pay the express fee Q3: Can you offer processing service? A: We can offer cutting, drilling, painting, coat powder etc... Q4: What is your advantage on steel? A: We can customize steel structure accoridng to buy's drawings or request. Q5: How about your logistic service? A: we have professional logistic team who has rich experience on shipping, can offer the steady and quality ship line. Market: We have built a long-term and stable cooperation relation with customers in domestic , such as Shanghai, Jiangsu, Zhejiang, Anhui,Shandong, Jiangxi, Qinghai, Liaoning, Hainan and so on. For overseas, our main client from South Asia, Africa, South America like Singapore, Vietnam, Brazil, Ghana, New Zealand, Spain, Mauritius, Dubai etc.

Mill Certificate:

Mill Certificate:  Advantage: Raw material is from Top manufacture which promise the high quality. Accurate technology confirm the exact size tolerance. Efficient sales team give you proper proposal. After-sales team offer and support for product guarantee. Quality Control:

Advantage: Raw material is from Top manufacture which promise the high quality. Accurate technology confirm the exact size tolerance. Efficient sales team give you proper proposal. After-sales team offer and support for product guarantee. Quality Control:  Our Service:

Our Service:  RFQ: Q1: Are you manufacture or Trader A: We are both manufacture and trader Q2: Can you offer sample? A: Sample small one can be offered by free, but buyer should pay the express fee Q3: Can you offer processing service? A: We can offer cutting, drilling, painting, coat powder etc... Q4: What is your advantage on steel? A: We can customize steel structure accoridng to buy's drawings or request. Q5: How about your logistic service? A: we have professional logistic team who has rich experience on shipping, can offer the steady and quality ship line. Market: We have built a long-term and stable cooperation relation with customers in domestic , such as Shanghai, Jiangsu, Zhejiang, Anhui,Shandong, Jiangxi, Qinghai, Liaoning, Hainan and so on. For overseas, our main client from South Asia, Africa, South America like Singapore, Vietnam, Brazil, Ghana, New Zealand, Spain, Mauritius, Dubai etc.

RFQ: Q1: Are you manufacture or Trader A: We are both manufacture and trader Q2: Can you offer sample? A: Sample small one can be offered by free, but buyer should pay the express fee Q3: Can you offer processing service? A: We can offer cutting, drilling, painting, coat powder etc... Q4: What is your advantage on steel? A: We can customize steel structure accoridng to buy's drawings or request. Q5: How about your logistic service? A: we have professional logistic team who has rich experience on shipping, can offer the steady and quality ship line. Market: We have built a long-term and stable cooperation relation with customers in domestic , such as Shanghai, Jiangsu, Zhejiang, Anhui,Shandong, Jiangxi, Qinghai, Liaoning, Hainan and so on. For overseas, our main client from South Asia, Africa, South America like Singapore, Vietnam, Brazil, Ghana, New Zealand, Spain, Mauritius, Dubai etc.